What Makes Lean Six Sigma Training Effective

Discover what makes Lean Six Sigma training effective and how it helps boost skills, cut waste, and improve results in any career path.

How can learning Lean Six Sigma help teams work faster and smarter?

Why are so many companies using this training to improve their processes?

In my experience with Lean Six Sigma, I’ve learned that training works best when it teaches people how to solve problems step by step, rather than just following rules.

In one of my early projects, we wanted to reduce mistakes in a production line. By looking at the main causes, making tasks simpler, and making sure everyone understood their role, we were able to reduce errors and improve the workflow. Lean Six Sigma taught me that small, consistent changes make a big difference over time.

According to Six Sigma, businesses that use Lean Six Sigma can reduce mistakes by up to 40%.

The American Society for Quality reports that process improvements can increase efficiency by 30%.

Teams trained in Lean Six Sigma often complete projects 20–25% faster than teams without training.

Understanding Lean Six Sigma Training

Lean Six Sigma Training blends two powerful methodologies:

-

Lean: Focuses on eliminating waste, improving flow, and delivering value faster.

-

Six Sigma: Uses statistical tools to reduce variation and improve quality.

When combined, they form a structured problem-solving approach that applies to every industry manufacturing, healthcare, IT, banking, and beyond.

Training equips professionals with tools like DMAIC (Define, Measure, Analyze, Improve, Control), root cause analysis, value stream mapping, and statistical process control.

The Role of Lean Six Sigma Training in Today’s Business

Today, markets change very fast, and customers want better things quickly. Lean Six Sigma Training helps businesses act fast when the market changes. It teaches teams how to find problems early and fix them quickly. From small companies to big ones, many are using Lean Six Sigma to make customers happy, stop waste, and keep growing.

Here are 4 key points you can add under that section:

-

Works for Any Business Size – From small shops to large companies, it can be used anywhere.

-

Saves Time and Money – Helps remove extra steps and reduce costs.

-

Improves Quality – Makes products and services better for customers.

-

Encourages Teamwork – Brings people together to solve problems.

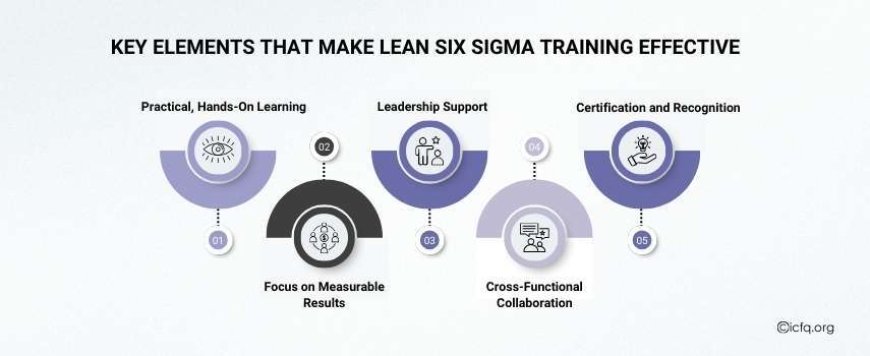

Key Elements That Make Lean Six Sigma Training Effective

1. Practical, Hands-On Learning

Theory alone doesn’t drive results. The most effective Lean Six Sigma Training programs incorporate real-world projects, simulations, and case studies.

-

Participants learn by applying tools to solve actual business problems.

-

This approach ensures they can use the methods confidently once training is complete.

2. Focus on Measurable Results

Lean Six Sigma is all about measurable improvement. Effective training programs teach participants to:

-

Define clear metrics for success.

-

Use data to track progress and verify outcomes.

-

Quantify cost savings, quality improvements, and time reductions.

3. Leadership Support

A company’s leadership must back Lean Six Sigma initiatives for them to work.

-

Effective programs involve training leaders alongside teams.

-

When leaders champion the methodology, it creates a culture where continuous improvement is valued.

4. Cross-Functional Collaboration

Lean Six Sigma breaks down silos.

-

Training encourages departments to work together on shared goals.

-

Cross-functional problem-solving often leads to innovative solutions that wouldn’t emerge in isolated teams.

5. Certification and Recognition

Whether it’s Yellow Belt, Green Belt, or Black Belt certification, structured training with recognized credentials boosts credibility.

-

Employees gain career advancement opportunities.

-

Organizations gain skilled problem-solvers who can lead improvement initiatives.

Industries Benefiting Most from Lean Six Sigma Training

-

Manufacturing: Minimized defects, better production flow.

-

Healthcare: Reduced patient wait times, improved safety.

-

Finance: Faster loan processing, fewer errors.

-

IT & Software: Streamlined development, reduced bug rates.

-

Retail: Optimized supply chains, enhanced customer service.

Common Mistakes That Can Reduce Training Effectiveness

Even with a great methodology, results can lag if:

-

The training is too theoretical with no practical application.

-

Leadership doesn’t actively support the process.

-

Teams fail to follow through after initial enthusiasm.

Why Lean Six Sigma Training Works Beyond Manufacturing

Some people think Lean Six Sigma Training is only useful for factories. In reality, it’s a flexible problem-solving method that works in many situations.

-

Adapts to Modern Challenges – Useful for digital transformation, AI projects, and managing remote teams.

-

Works With Data Tools – Fits well with modern analytics for faster, fact-based decisions.

-

Fits All Industries – Helps in healthcare, IT, finance, and service sectors, not just manufacturing.

-

Supports Continuous Improvement – Keeps processes updated as technology and customer needs change.

-

Reduces Errors in Complex Systems – Identifies and corrects errors in even the most advanced digital systems.

The effectiveness of Lean Six Sigma Training lies in its ability to empower employees, align them with business goals, and equip them with tools for measurable improvement. Companies that treat it as more than just a certification and instead as a long-term strategy gain a competitive edge.

Whether you’re aiming to cut costs, improve quality, or streamline processes, Lean Six Sigma provides a proven framework to achieve your goals.

If you want to explore how Lean Six Sigma Training can transform your business, reach out to our experts at [email protected]