What is a Lean Six Sigma White Belt?

Learn what a Lean Six Sigma White Belt is, its role, benefits, and how it builds the foundation for process improvement and quality management success.

If you’ve heard terms like “Green Belt” or “Black Belt” in process improvement, you may be surprised to learn that they start with the White Belt.

A Lean Six Sigma White Belt is the entry level of certification in the Lean Six Sigma methodology, a way organisations improve how they work, reduce waste, and raise quality.

By learning the White Belt concepts, both employees and organisations can start transforming the way they work, making processes faster, smarter, and more efficient.

What Is a Lean Six Sigma White Belt?

At its core, the Lean Six Sigma White Belt represents basic awareness of both the Lean and Six Sigma approaches. The “Lean” side focuses on eliminating waste and speeding up processes; the “Six Sigma” side focuses on reducing variation and defects.

A White Belt certification shows that you understand the foundational concepts: what process improvement means, what the DMAIC framework is (Define, Measure, Analyze, Improve, Control), and where you might fit in a larger improvement project.

It’s a stepping stone, you’re not yet leading projects, but you’re aware of key terminology and can provide support to improvement efforts.

Why Does It Matter?

For Individuals

-

Builds foundational skills: Even a White Belt helps you speak the same language as improvement teams and shows you know what improvement initiatives are about.

-

Career value: For entry-level professionals, having this certification can help you stand out and show your employer you understand quality and process improvement.

-

Gateway to more advanced belts: After White Belt, you may move to the Yellow, Green, or Black Belt levels over time as your skills grow.

For Organisations

-

Baseline process culture: If many team members hold White Belts, you create a common understanding of improvement across departments.

-

Support for improvement projects: White Belt holders can assist in data collection, process mapping, and help improvement teams operate more smoothly.

-

Cost-effective training: Since White Belt training is shorter and less in-depth than higher belts, it can be used broadly across staff to raise overall awareness.

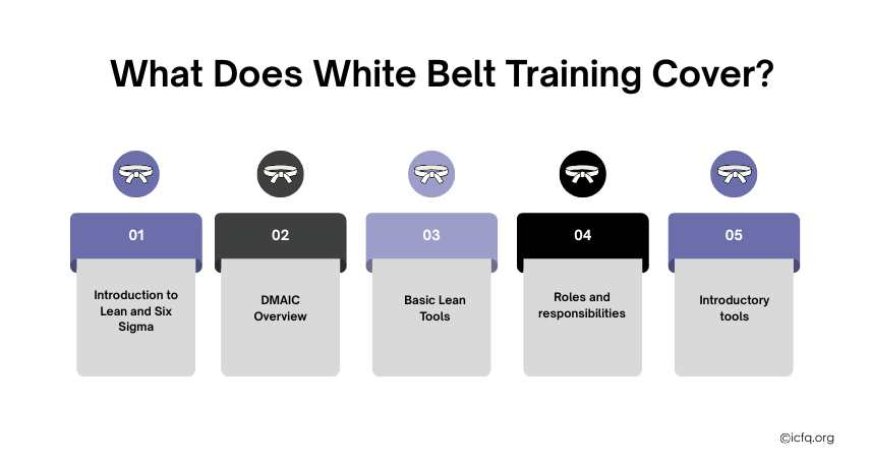

What Does White Belt Training Cover?

The White Belt training is short, introductory, and focuses on key concepts. Here are common topics:

-

Introduction to Lean and Six Sigma: Origins, purpose, and how they work together.

-

DMAIC Overview: Define, Measure, Analyze, Improve, Control — the main steps of Six Sigma.

-

Basic Lean Tools: Concepts such as waste (muda), value stream, flow, 5S, etc.

-

Roles and responsibilities: Understanding where White Belts fit and how they support higher-level belts.

-

Introductory tools: Process mapping (SIPOC), cause-and-effect diagrams, basic metrics.

The goal is not to master data analysis or lead large projects, those come later, but to gain clarity about the improvement journey and how you can participate.

Who Should Take a White Belt?

The White Belt is ideal for:

-

New professionals or support staff who want to understand process improvement.

-

Team members who participate in projects rather than lead them.

-

Departments that want a shared vocabulary on improvement across operations, quality, or services.

-

Organisations that aim to embed continuous improvement across many roles.

According to sources, White Belts are useful across industries manufacturing, healthcare, IT, and finance, anywhere process efficiency matters.

What Are the Business Benefits?

For companies, here are the key benefits of having White Belt-certified employees

-

Improved process awareness: Team members understand what improvement means and can spot issues early.

-

Better support for projects: White Belts provide data collection, process mapping, and help time improvement efforts more efficiently.

-

Cost savings: Early intervention of inefficiencies reduces waste, rework, and improves productivity.

-

Stronger improvement culture: When many employees share the same foundational knowledge, the organisation is more prepared to take on bigger improvement initiatives.

How Does White Belt Fit Into the Belt System?

Here’s a quick view of how White Belt compares to other belts:

-

White Belt: Basic understanding; supports improvement teams.

-

Yellow Belt: Deeper knowledge; actively participates in projects.

-

Green Belt: Leads smaller projects; uses statistical tools.

-

Black Belt / Master Black Belt: Leads major initiatives, mentors others, and uses advanced data analysis.

In many organisations, you don’t have to complete White before Yellow, some skip levels if qualified, but the White Belt remains the foundation

Tips for Success as a White Belt

Whether you’re a team member or aspiring to grow, here are some good practices:

-

Sit in and support actual improvement projects to gain real experience.

-

Learn and use standard tools (process maps, cause-and-effect diagrams).

-

Communicate results clearly, use simple language, and use visual tools.

-

Adopt a mindset of continuous improvement, always ask “How can this process be smoother?”

-

Stay curious, attend Yellow or Green Belt sessions as you progress.

A Lean Six Sigma White Belt is more than just a certificate, it’s a foundational tool for building a culture of improvement. It lets you understand how processes work, where things can go wrong, and how to fix them. For individuals, it improves their value and visibility. For organisations, it strengthens their foundation and readiness for larger change initiatives.

By starting with the White Belt, you’re stepping into a journey of continuous improvement and a smarter way to work.