Want Better Efficiency? Get Your Yellow Belt Now!

Boost work efficiency and reduce errors with a certified Six Sigma Yellow Belt. Learn process improvement, problem-solving, and team productivity skills today.

Do you feel like your team could do more in less time?

Are deadlines always stressful, and tasks seem harder than they should be? The secret to working smarter and faster often lies in Six Sigma, and starting with a Yellow Belt can help you get there.

From my experience, I realized that doing work in a smart way, not just harder, can save a lot of time and reduce mistakes. When I earned my Yellow Belt certification, I learned how to look closely at processes, spot problems, and fix them. It wasn’t just helpful for me; I could see my whole team working smoothly and achieving more because of it.

What is a Yellow Belt?

A certified Six Sigma Yellow Belt is the first level of Six Sigma certification. It is for people who want to learn how to improve work processes. You do not need to be an expert in math or data. Certified Six Sigma Yellow Belt training focuses on:

-

Finding problems in work processes.

-

Learning simple tools like DMAIC (Define, Measure, Analyze, Improve, Control).

-

Helping in projects that improve how work is done.

Even small improvements learned in certified Six Sigma Yellow Belt training can save time, reduce mistakes, and make work easier for everyone.

How a Yellow Belt Improves Efficiency

A Yellow Belt helps you work smarter, save time, and reduce mistakes. Here are some key ways it improves efficiency:

-

Streamlined Processes – You learn to remove unnecessary steps in work. For example, if a team has too many approval steps for a simple task, a Yellow Belt can suggest combining or removing steps, saving hours every week.

-

Data-Driven Decisions – Instead of guessing, you learn to use data to find problems and solutions. For instance, tracking how long each task takes helps you identify bottlenecks and fix them quickly.

-

Better Team Communication – Yellow Belts understand processes clearly, so they can explain issues and solutions to team members easily. This reduces misunderstandings and repeated work.

-

Employee Confidence – Knowing how to improve processes makes you feel more confident at work. You can suggest solutions and see the positive impact, which motivates both you and your team.

-

Error Reduction – By analyzing work steps and following the DMAIC method, mistakes are caught early before they affect the outcome. This leads to higher quality work with less rework.

-

Time Savings – Even small improvements in each process step add up. Over weeks and months, this can save hours of work for you and your team, freeing up time for more important tasks.

Benefits of Getting a Yellow Belt

Earning a Yellow Belt brings many advantages, not just for your career but also for your team and organization. Here’s how it helps:

-

Better Understanding of Work – You learn how processes really work and where problems happen. For example, you might see that a task takes longer than necessary because of repeated approvals, and you can suggest a simpler approach.

-

Problem-Solving Skills – Yellow Belt training teaches you to find the real cause of issues, not just fix the symptoms. This means problems are solved once and for all, instead of coming back repeatedly.

-

Career Growth – Employers value people who can improve work and save time. Being a Yellow Belt can make you stand out for promotions or leadership opportunities.

-

Improved Teamwork – You can contribute more effectively in team projects because you understand processes and know how to improve them. This helps the team achieve better results faster.

-

Clear Communication – With Yellow Belt knowledge, you can explain problems and solutions to your team in simple terms. This reduces confusion and ensures everyone is on the same page.

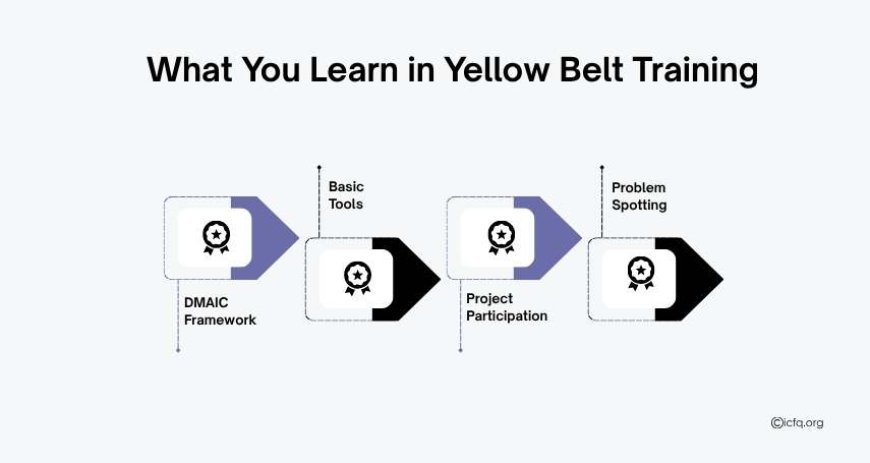

What You Learn in Yellow Belt Training

Yellow Belt training teaches important skills that help you improve efficiency:

-

DMAIC Framework – Learn to define problems, measure results, analyze causes, improve processes, and control results to keep improvements.

-

Basic Tools – Use simple diagrams, charts, and maps to understand processes and spot problems.

-

Project Participation – Help in real work projects led by experienced team members.

-

Problem Spotting – Learn to identify small issues before they become big problems.

These skills make you confident in improving your own work and helping your team.

Yellow Belt vs Other Six Sigma Levels

|

Feature |

Yellow Belt |

Green Belt |

Black Belt |

|

Knowledge |

Basic understanding |

More detailed |

Expert |

|

Role |

Team member |

Project leader |

Strategic leader |

|

Training Time |

2–5 days |

2–3 weeks |

4–6 weeks |

|

Focus |

Process basics & simple fixes |

Improve and analyze processes |

Lead big projects & complex problems |

|

Best For |

Beginners |

Mid-level managers |

Senior managers |

This table shows why the Yellow Belt is the best starting point if you are new to process improvement.

How to Get Your Yellow Belt

Earning a Yellow Belt is easier than you might think. By following these steps, you can gain valuable skills to improve work efficiency and help your team succeed.

1. Choose a Good Training Program

Start by finding a recognized training program with experienced instructors and good reviews. Look for programs that offer easy-to-understand lessons and practical examples. Some programs are online, while others are in-person. Choose one that fits your schedule and learning style.

2. Complete the Training

During the training, you will learn the basics of DMAIC (Define, Measure, Analyze, Improve, Control), simple process maps, and problem-solving techniques. Pay attention to practical tips that you can use in your daily work.

The training usually includes videos, quizzes, and exercises to help you understand concepts. Take your time to practice each step so you feel confident applying it later.

3. Practice Your Skills

After learning the basics, try to practice your skills at work. Start with small projects or tasks where you can apply process improvement techniques. For example:

-

Identify steps in a task that take too long.

-

Suggest a simpler way to do the work.

-

Track results to see if the new process is faster or more accurate.

Practical experience is key to understanding how Yellow Belt skills work in real life.

4. Get Certified

Most Yellow Belt programs require you to pass a short exam or complete a simple project to earn your certificate. The exam usually tests your knowledge of basic tools, process improvement methods, and DMAIC steps.

Completing a small project shows that you can apply your learning to real work situations, which is often more valuable than just passing a test.

5. Apply Your Knowledge at Work

Once certified, start using your Yellow Belt skills to make a real difference at work. You can:

-

Suggest improvements in daily processes.

-

Track results to show measurable benefits.

-

Help your team work faster and with fewer mistakes.

-

Share your learning with others to create a culture of improvement.

Even small improvements can save hours of work each week and increase overall efficiency. The more you practice, the more confident you become in identifying problems and solving them smartly.

Earning a Yellow Belt is a powerful way to improve your work and your team’s efficiency. It teaches you how to understand processes, spot problems, and make smart improvements. The skills you gain help reduce mistakes, save time, and make work smoother for everyone.

The true value comes when you apply what you learn consistently, starting with small changes, tracking results, and celebrating improvements. Over time, these efforts add up, helping you and your team achieve better results with less effort.