Which Six Sigma Tools Actually Work?

Learn which Six Sigma tools drive real process improvement, reduce variation, and help businesses achieve consistent quality and efficiency.

Ever feel like your team spends hours analyzing problems but still struggles to fix them?

You follow every Six Sigma step, draw charts, measure data - yet improvement feels slow.

If you’ve asked yourself, “Are these tools even working?” - you’re not alone.

Here’s the truth: not every Six Sigma tool creates results.

Some look good on paper but fail to make real change.

The key isn’t using all the tools - it’s knowing which ones actually move the needle.

The New Business Reality: Efficiency Is the Real Profit

In the race for quality and consistency, success isn’t about doing more - it’s about doing better.

According to the American Society for Quality (ASQ), companies that implement Six Sigma tools effectively achieve:

-

Up to 50% reduction in process variation

-

30% lower operational costs

-

40% higher customer satisfaction

That’s not luck - it’s precision.

Businesses that use the right tools see consistent, measurable performance improvement.

Yet many teams still get lost in spreadsheets, meetings, and analysis paralysis.

Because they’re focused on using all the tools - instead of the right ones.

Why Some Six Sigma Tools Fail to Deliver

Six Sigma is powerful, but it’s easy to misuse.

Most failures happen when teams:

-

Collect data without context

-

Use charts without insights

-

Focus on numbers, not behavior

The truth is - tools don’t fix problems. People do.

Six Sigma tools work best when they help you see clearly, decide quickly, and act confidently.

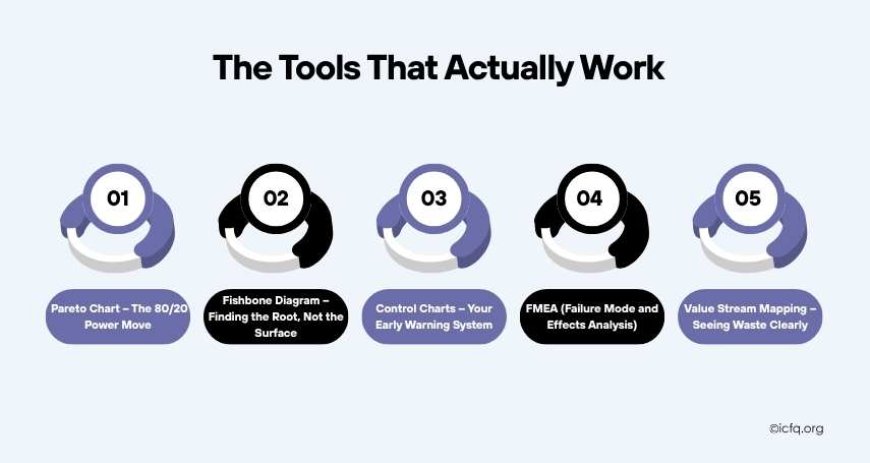

The Tools That Actually Work

Let’s cut the noise.

Here are the Six Sigma tools that deliver proven results across real-world industries.

1. Pareto Chart – The 80/20 Power Move

Ever heard the saying “80% of results come from 20% of causes”?

That’s what the Pareto Chart reveals.

It helps teams identify the vital few issues causing the majority of problems.

Why it works:

It simplifies complex data and directs focus where it matters most - the biggest impact areas.

Instead of chasing every error, teams solve what truly drives results.

2. Fishbone Diagram – Finding the Root, Not the Surface

The Cause-and-Effect (Ishikawa or Fishbone) Diagram helps teams find why problems occur — not just where.

It breaks issues into categories like methods, materials, manpower, and machinery.

Why it works:

It encourages deep thinking and collaboration.

When teams map every possible cause visually, they uncover hidden inefficiencies that data alone can’t show.

3. Control Charts – Your Early Warning System

Control Charts track process performance over time.

They show whether variations are normal or signs of something going wrong.

Why it works:

It helps detect issues before they turn into defects.

Instead of reacting to failure, teams act proactively - saving both time and cost.

4. FMEA (Failure Mode and Effects Analysis)

FMEA identifies all possible ways a process can fail and ranks them by severity, likelihood, and detectability.

Why it works:

It transforms guesswork into foresight.

Companies like Ford and General Electric rely on FMEA to predict issues before launch - minimizing costly recalls.

5. Value Stream Mapping – Seeing Waste Clearly

This visual tool maps every step of your process to spot non-value-adding activities.

Why it works:

It highlights where time, money, and effort are being wasted.

When Toyota adopted this method, production times improved dramatically - proving visibility drives efficiency.

When Tools Become Transformation

When used right, Six Sigma tools do more than optimize - they transform.

They create a culture of:

-

Problem-solving instead of blame

-

Data-based decisions instead of assumptions

-

Continuous improvement instead of temporary fixes

And that’s where Six Sigma becomes more than a methodology - it becomes a mindset.

The Hidden Reason Teams Struggle

Most businesses don’t fail because the tools are wrong - they fail because the mindset is.

Teams often treat Six Sigma like a one-time project instead of a continuous journey.

But improvement isn’t an event - it’s an evolution.

The most successful companies - like Motorola, GE, and 3M don’t just use Six Sigma tools.

They live them.

They embed problem-solving, measurement, and accountability into every level of their operations.

When Data Meets Decisions: Turning Insights into Action

Collecting data is easy - turning it into meaningful action is where real improvement happens. Many Six Sigma projects stall because teams analyze endlessly but hesitate to decide.

The truth? Data is only as powerful as the decisions it drives.

When teams use Six Sigma tools like Pareto Charts or Control Charts, the goal shouldn’t stop at measurement - it should lead to change.

A successful Six Sigma culture ensures that every insight sparks a decision, every decision leads to action, and every action is measured for impact.

That’s how companies move from analysis to achievement.

Create a “Decision Log” - a simple record of what insights led to what actions. Over time, this connects data with tangible outcomes, reinforcing accountability and continuous growth.

How to Make Six Sigma Work for You

You don’t need to master every tool - you need to master the right ones for your business.

Here’s how to start:

-

Identify your biggest process pain points.

-

Use Pareto Charts to target the top causes.

-

Apply Fishbone Diagrams to explore root causes.

-

Use FMEA to predict and prevent failures.

-

Monitor results with Control Charts.

-

Visualize and refine workflows using Value Stream Mapping.

Start small. Measure everything. Improve continuously.

Because Six Sigma isn’t just about data — it’s about discipline.

The Real Payoff: Consistency Builds Trust

Customers don’t stay loyal to brands that are perfect - they stay loyal to brands that are consistent.

Six Sigma helps you deliver that consistency.

It gives you control, visibility, and confidence in your process.

In a world where efficiency is the new edge, Six Sigma tools are your foundation for quality that lasts.

Don’t Overcomplicate It - Simplify It

At the end of the day, Six Sigma isn’t about how many charts you can make

It’s about how many problems you can solve.

The real improvement starts not when you use every tool, but when you use the right one, the right way.

So, the next time you start a project, ask yourself:

“Am I applying a tool - or solving a problem?”

Because the companies that thrive aren’t the ones that work harder.

They’re the ones that work smarter - with precision, clarity, and the right tools.