How Process Optimization Strategies Reduce Errors and Save Time

Learn how process optimization strategies help businesses reduce operational errors, improve workflow efficiency, and save time through structured improvements.

In every growing business, teams eventually reach a point where they feel stuck. Deadlines slip. Errors keep repeating. Workloads increase, but output does not. If you’ve ever wondered “Why are simple tasks taking so long?” or “Why does the same mistake happen again and again?”, the answer often lies in the process - not the people.

This is where process optimization strategies become essential. Modern organizations use them to create leaner workflows, minimize bottlenecks, reduce operational waste, and most importantly, save time while improving accuracy.

A well-optimized process is more than a productivity booster. It is a core business asset that directly impacts customer satisfaction, profitability, employee morale, and long-term scalability.

Why Process Optimization Matters - Key Metrics to Consider

Across industries, optimized processes have delivered measurable improvements such as:

-

30–50% reduction in repetitive manual errors through workflow standardization and automation.

-

20–40% improvement in turnaround times, especially in operations, HR, finance, and customer support.

-

15–25% cost savings driven by faster delivery, better resource allocation, and reduced rework.

These metrics highlight a clear truth: optimizing processes isn’t about working harder - it’s about working smarter.

Toyota’s Lean Manufacturing Revolution

Toyota is one of the world’s best examples of how process optimization transforms an organization.

In the early 1950s, Toyota faced production delays, errors on the assembly line, and unpredictable quality.

Instead of simply adding more manpower, they redesigned their manufacturing system using the now-famous Toyota Production System (TPS), a combination of lean process optimization, continuous improvement (Kaizen), and waste elimination practices.

Results:

-

Reduced manufacturing defects significantly

-

Increased production speed

-

Set a global benchmark for operational excellence

Today, Toyota’s success is a reminder that systems outperform effort. When processes work smoothly, people can do their best work without being slowed down by inefficiencies.

What Is Process Optimization

Process optimization is the structured method of improving business workflows to achieve:

-

Faster task execution

-

Reduced human error

-

Better resource utilization

-

Consistent quality

-

Lower operational costs

It involves assessing existing processes, identifying gaps, and redesigning workflows to improve efficiency.

How Process Optimization Strategies Reduce Errors and Save Time

Below are the most effective, proven strategies organizations use to eliminate mistakes and improve speed.

1. Eliminating Manual and Repetitive Tasks with Automation

Manual tasks are the biggest source of errors and time delays. Typing data, updating spreadsheets, sending reminders, or processing routine documents consume hours that could be spent on strategic work.

How automation helps:

-

Reduces human involvement in repetitive tasks

-

Eliminates typographical and calculation errors

-

Standardizes workflow outputs

-

Accelerates task completion

Tools such as CRM automations, workflow automation software, and AI-powered process systems improve accuracy while saving hours per employee every week.

Example:

Finance teams often spend long hours manually updating invoice details. Automating this workflow cuts processing time by up to 70% and drastically reduces data-entry errors drastically.

2. Standard Operating Procedures (SOPs) for Consistency

Without defined steps, every employee performs a task differently. This inconsistency leads to errors, delays, and miscommunication.

SOPs ensure:

-

Clear guidelines for every process

-

Standardized outputs

-

Fewer mistakes caused by guesswork

-

Faster onboarding for new employees

Documented steps also help detect gaps quickly and ensure everyone follows the same quality standards.

3. Identifying Bottlenecks Through Process Mapping

Businesses often believe they know where the problem lies - until they map it visually.

Process mapping helps teams identify:

-

Hidden delays

-

Duplicate tasks

-

Unnecessary approvals

-

Misaligned responsibilities

-

Resource wastage

Once the workflow is mapped, inefficiencies become obvious. Teams can redesign the process for faster execution and clear responsibility distribution.

Result:

Reduced back-and-forth communication, faster decision-making, and fewer errors caused by confusion.

4. Data-Driven Decision Making

Process optimization is most effective when decisions are based on real data, not assumptions.

Organizations use data to track:

-

Error frequency

-

Task completion time

-

Customer complaints

-

Rework rates

-

Employee performance gaps

With data analytics, businesses can understand what’s slowing performance and implement targeted improvements.

Example:

If customer support data reveals that 40% of delays occur during ticket assignment, automated ticket routing can eliminate the bottleneck.

5. Lean Methodology to Eliminate Waste

Lean methodology focuses on removing activities that don’t add value.

Types of “waste” in processes include:

-

Waiting times

-

Extra approvals

-

Unnecessary documentation

-

Over-processing

-

Rework

-

Inefficient handovers

Eliminating such waste results in faster delivery, less confusion, and highly efficient workflows.

6. Continuous Improvement (Kaizen Approach)

Optimization is never a one-time project. As business needs evolve, processes must evolve too.

Continuous improvement encourages:

-

Regular feedback

-

Testing new workflows

-

Measuring outcomes

-

Updating processes frequently

This ensures errors are caught early and processes remain aligned with business goals.

7. Enhancing Communication and Collaboration

Many errors occur not due to technical issues but due to miscommunication.

Common problems include:

-

Missing information

-

Incorrect task handover

-

Confusing expectations

-

Lack of real-time updates

Using collaboration tools and structured communication guidelines ensures clarity, reduces misunderstanding, and speeds up workflow execution.

8. Training and Skill Development

Optimized processes work only when employees fully understand them.

Structured training helps teams:

-

Learn best practices

-

Avoid mistakes

-

Use tools efficiently

-

Adapt to new workflows

-

Deliver higher-quality output

Better-skilled employees reduce error rates and complete tasks much faster.

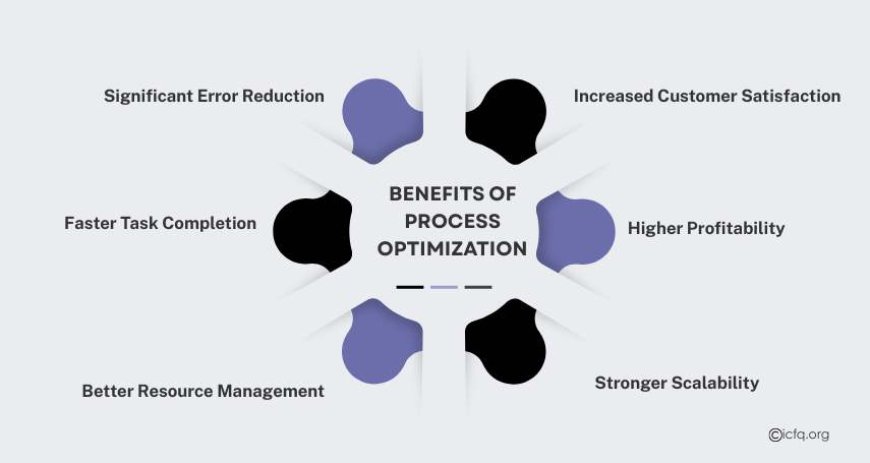

Benefits of Process Optimization: How It Transforms Your Business

When executed correctly, process optimization delivers long-term operational advantages.

1. Significant Error Reduction

Automated workflows, SOPs, and clear documentation ensure fewer:

-

Data-entry mistakes

-

Miscommunications

-

Incorrect outputs

-

Redundant approvals

This leads to more predictable and reliable results.

2. Faster Task Completion

Streamlined processes remove unnecessary steps and reduce waiting times. Employees gain extra productive hours that can be redirected toward strategic work.

3. Better Resource Management

Optimized processes prevent overwork, reduce burnout, and ensure resources are allocated where they create the most value.

4. Increased Customer Satisfaction

Faster turnaround times and fewer mistakes lead to better service delivery, ultimately driving customer retention and trust.

5. Higher Profitability

Reduced rework, faster output, and better workflow management naturally lead to lower operational costs and greater profit margins.

6. Stronger Scalability

Businesses with optimized processes scale faster because:

-

Workflows are already structured

-

Systems operate efficiently

-

Additional resources integrate smoothly

This is essential for companies planning growth or expansion.

Process Optimization Is No Longer Optional

For modern organizations, process optimization is essential for maintaining accuracy, efficiency, and competitive advantage. Whether you are a small business or an enterprise, optimizing your workflows allows your teams to deliver faster, reduce errors, and operate with confidence.

Businesses that invest in process optimization see long-term benefits such as improved productivity, reduced operational costs, better customer experiences, and stronger scalability.

The goal isn’t just to fix today’s problems but to build a system that avoids future issues, allowing your team to focus on innovation rather than reactive problem management

If your business wants to grow, the question isn’t whether to optimize processes - but when you choose to replace outdated workflows with streamlined, high-performing systems