What is DFSS and Why It’s Important in Quality Management

Learn what DFSS (Design for Six Sigma) means, how it improves quality management, and why it helps businesses design better, efficient processes.

Every day, professionals look for ways to grow their careers and get ahead in a competitive job market. One skill that is highly valued today is DFSS (Design for Six Sigma), which helps improve processes and make better products.

The interesting part is, there is not just one place that gives DFSS certification. Many trusted organizations offer training and certificates, and each has its own exams and recognition.

Choosing the right DFSS program matters. The certificate you earn shows your skills, your knowledge of process improvement, and your ability to lead change in a company.

What is DFSS?

DFSS stands for Design for Six Sigma. It is a method that helps companies design products, services, or processes that meet customer needs with very few errors.

Unlike traditional Six Sigma, which tries to fix problems in existing products or processes, DFSS is preventive. This means it tries to avoid problems before they happen.

The main goal of DFSS is to make sure the product or service works well, is reliable, and satisfies the customer. Using DFSS saves money, reduces rework, and improves customer satisfaction.

Main Ideas of DFSS

DFSS has some important ideas that guide companies to create good products:

-

Customer Focus

Always start by understanding what the customer wants. Ask questions like: What do they like? What problems do they face? This helps design the product the right way.

-

Plan for Quality Early

Instead of fixing problems later, DFSS plans for quality from the start. It tries to remove mistakes before production begins.

-

Use Data to Make Decisions

All decisions are based on data, not guesses. Companies use numbers, statistics, and analysis to make sure the design will work.

-

Teamwork Across Departments

DFSS needs input from different teams, like engineering, marketing, operations, and quality, to create a product that works well and is easy to make.

-

Manage Risks

DFSS helps find possible problems early so they can be avoided. This reduces risks like customer complaints, returns, or safety issues.

How DFSS Works

DFSS usually uses step-by-step methods to design products. Two common methods are:

1. DMADV

DMADV stands for Define, Measure, Analyze, Design, Verify.

-

Define: Decide what the customer wants and what the project goal is.

-

Measure: Identify important measurements for success.

-

Analyze: Check different design options and choose the best one.

-

Design: Create the product or process according to the plan.

-

Verify: Test the design to make sure it works and meets customer needs.

2. IDOV

IDOV stands for Identify, Design, Optimize, Validate.

-

Identify: Find the problem or opportunity.

-

Design: Make different design ideas and compare them.

-

Optimize: Improve the design to meet goals for cost and performance.

-

Validate: Test to confirm the design meets all requirements before production.

Both methods aim to build quality into the product from the start.

Why DFSS is Important

Using DFSS brings many benefits to a company:

-

Fewer Mistakes and Rework

Planning quality from the start reduces defects and avoids fixing problems later.

-

Happy Customers

Products designed with DFSS meet customer expectations. When products work as promised, customers trust the brand.

-

Saves Money

Fixing problems after production is expensive. DFSS helps prevent these costs by catching issues early.

-

Encourages Innovation

DFSS allows teams to explore new ideas while keeping designs practical and reliable.

-

Better Efficiency

Well-designed products or processes are easier to make, maintain, and operate. DFSS helps create smooth and efficient workflows.

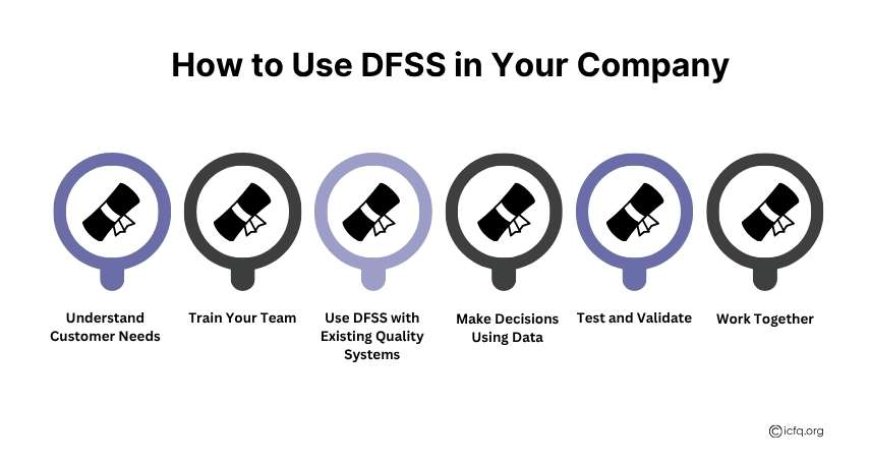

How to Use DFSS in Your Company

Here are some simple steps to start using DFSS:

-

Understand Customer Needs

Collect information about what customers want and expect. Surveys, interviews, and feedback can help.

-

Train Your Team

Employees should learn DFSS methods and tools like FMEA (Failure Mode and Effects Analysis) or DOE (Design of Experiments).

-

Use DFSS with Existing Quality Systems

DFSS works best alongside systems like ISO 9001 or Lean Six Sigma.

-

Make Decisions Using Data

Use historical data, research, and simulations to plan the design.

-

Test and Validate

Check the prototypes and designs carefully to make sure they meet requirements.

-

Work Together

Teams from different departments should collaborate from the beginning to avoid mistakes and redesigns later.

Best Practices for DFSS

-

Start Small: Begin with a small project to learn DFSS before applying it to bigger products.

-

Keep Records: Document all design choices and tests.

-

Train Regularly: Keep teams updated on DFSS tools and methods.

-

Use Technology: Software for modeling and analysis helps improve designs.

-

Align with Business Goals: Make sure DFSS efforts support company objectives, like saving costs or improving customer satisfaction.

Future of DFSS

DFSS is becoming more important as industries grow more complex:

-

Digital Products: DFSS helps design IoT devices, apps, and smart gadgets reliably.

-

Healthcare: Medical devices and drugs need high quality and safety, which DFSS supports.

-

Automotive and Aerospace: Complex systems require reliable designs to prevent failures.

-

Sustainable Manufacturing: DFSS helps reduce waste and use resources efficiently while keeping quality high.

DFSS combines data, analysis, and proactive planning to create products that are reliable, safe, and cost-effective.

DFSS (Design for Six Sigma) is a powerful way to improve processes, reduce errors, and create better products. By learning DFSS and getting certified, you show that you have the skills to design quality into every project and help your company succeed.

Choosing the right certification program is important because it reflects your knowledge, abilities, and readiness to lead improvements. Investing in DFSS training is not just about earning a certificate, it’s about building a stronger career and making a real impact in your workplace.