DMADV vs DMAIC: Find the Best Fit for Projects

Discover the key differences between DMADV and DMAIC to choose the right method for your project success. Simple, clear, and practical insights.

Do you ever wonder whether your business needs to improve existing processes or build entirely new ones? And how do you know which Six Sigma methodology, DMADV or DMAIC, is the right choice for your project?

In my experience with Six Sigma, I’ve seen that the true power of these methodologies isn’t just in knowing the steps, it’s in understanding when and how to apply them. While DMAIC strengthens what already exists, DMADV ensures that new designs are customer-focused and sustainable.

The choice between DMADV and DMAIC can significantly impact project success, cost savings, and long-term results. A company that applies the wrong framework risks wasting resources and stalling growth, but when the right one is chosen, the benefits extend well beyond efficiency; they drive innovation, resilience, and competitive advantage.

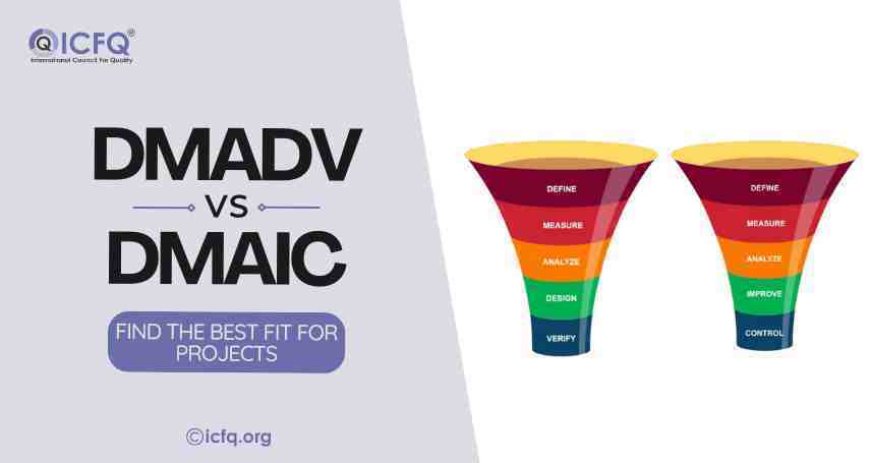

What is DMAIC?

DMAIC stands for Define, Measure, Analyze, Improve, and Control. It is a core Six Sigma methodology designed to improve existing processes. Companies use DMAIC when performance gaps, inefficiencies, or quality issues exist in their operations.

What is DMADV?

DMADV stands for Define, Measure, Analyze, Design, and Verify. Unlike DMAIC, DMADV focuses on creating new processes, products, or services from scratch while ensuring they meet customer expectations and quality standards.

Why DMADV vs DMAIC Matters for Businesses

In Six Sigma, two widely used methodologies are DMAIC and DMADV. Both aim to improve business performance, but they serve different purposes depending on the situation.

DMAIC (Define, Measure, Analyze, Improve, Control) is used to improve existing processes by identifying inefficiencies, fixing problems, and maintaining long-term stability. For example, a manufacturer may apply DMAIC to reduce assembly line errors.

DMADV (Define, Measure, Analyze, Design, Verify) is used to create new processes or products from scratch, ensuring they meet customer needs and deliver long-term success. Companies often use DMADV when launching new products or services.

|

Aspect |

DMAIC |

DMADV |

|

Purpose |

Focused on improving existing processes that are underperforming by identifying inefficiencies and reducing variations. |

Focused on designing new processes or products from the ground up to meet customer requirements and market needs. |

|

Focus |

Emphasizes problem-solving and optimization to bring stability and consistency in ongoing operations. |

Emphasizes innovation, customer-centric design, and long-term success for new solutions. |

|

Outcome |

Results in efficiency gains, reduced defects, cost savings, and better process control for established workflows. |

Results in new designs, enhanced quality, competitive advantage, and alignment with customer expectations. |

|

Tools Used |

Relies on root cause analysis, process mapping, statistical analysis, and control charts to fix existing flaws. |

Uses predictive modeling, design optimization, simulation, and failure mode analysis to ensure robust design. |

|

Best For |

Ideal for incremental improvements in manufacturing, services, or operations where processes already exist. |

Ideal for breakthrough innovation, new product launches, or when existing processes cannot meet future demands. |

|

Risk Level |

Lower risk since it works on processes that are already in place and only need adjustments. |

Higher risk as it involves designing entirely new processes, but offers greater long-term rewards. |

|

Example Use Case |

A telecom company is applying DMAIC to reduce dropped call rates in an existing network system. |

A tech company using DMADV to design a new AI-driven customer service platform from scratch. |

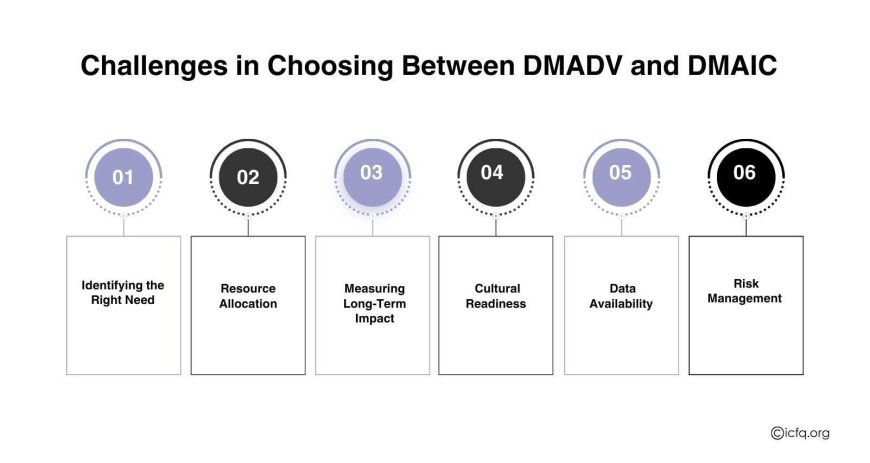

Challenges in Choosing Between DMADV and DMAIC

Selecting between DMADV and DMAIC may seem straightforward, but businesses often face several challenges before making the right choice.

1. Identifying the Right Need

Many organizations struggle to decide whether the issue lies in an existing process or whether a completely new design is required. Misjudging this can lead to wasted time and resources.

2. Resource Allocation

DMAIC often demands fewer resources since it works on existing systems, while DMADV may require larger budgets, skilled teams, and more time. Businesses must carefully evaluate if they can execute either method effectively.

3. Measuring Long-Term Impact

DMAIC delivers quicker, visible results, but DMADV focuses on long-term innovation. Companies may find it difficult to balance short-term gains with future growth objectives.

4. Cultural Readiness

DMAIC requires a problem-solving mindset, while DMADV calls for creativity and openness to innovation. Organizations not culturally aligned with these approaches may resist the changes required.

5. Data Availability

Both methodologies rely heavily on accurate data. For DMAIC, historical process data is critical, whereas DMADV requires customer insights and market research. Poor data quality can hinder results in either approach.

6. Risk Management

DMAIC generally carries lower risk since it improves what already exists, while DMADV involves building something new with uncertainties. Businesses often struggle to assess if they are ready to handle that risk.

How to Select the Right Methodology for Your Project

Choosing between DMADV and DMAIC is not just about following Six Sigma rules; it’s about aligning the methodology with your business goals. The right choice ensures efficient use of resources, higher ROI, and long-term process stability.

1. Define Your Objective Clearly

If you aim to fix inefficiencies in an existing process, DMAIC is the best choice. If you want to design a new process or product that meets customer needs, DMADV is the better option.

2. Assess the Current State of Processes

Start by asking: Is the existing process salvageable? If yes, DMAIC works best. But if the process is outdated or cannot meet customer expectations even after improvements, DMADV should be applied.

3. Evaluate Resource Availability

DMAIC requires moderate resources, while DMADV demands more investment in research, design, and testing. Businesses should check if they have the right talent, time, and budget.

4. Consider Customer Expectations

For customer-driven industries like healthcare, fintech, or retail, DMADV may be more suitable when designing innovative solutions. DMAIC, on the other hand, fits well for enhancing service delivery or reducing operational errors.

5. Weigh Risk vs. Reward

DMAIC usually has lower risk since it works on proven systems, while DMADV carries higher uncertainty but also higher potential rewards in terms of innovation and market differentiation.

Future Trends: Blending DMADV and DMAIC with Emerging Technologies

The future of Six Sigma lies in combining traditional methodologies like DMADV and DMAIC with modern technologies. Businesses are realizing that improvement and innovation are no longer separate paths; they must work together to stay competitive.

1. AI-Driven Decision Making

Artificial Intelligence (AI) is transforming how organizations apply DMADV and DMAIC. In DMAIC, AI can analyze massive process data to identify inefficiencies faster, while in DMADV, AI-powered predictive models help design new products that match evolving customer demands.

2. Integration with Big Data Analytics

Big Data provides real-time insights into supply chains, customer behavior, and operations. DMAIC leverages this to refine existing processes, whereas DMADV uses predictive analytics to test designs virtually before implementation, reducing risks and costs.

3. IoT for Real-Time Monitoring

The Internet of Things (IoT) connects machines, systems, and processes in real time. For DMAIC, IoT devices enable continuous monitoring and control of performance. For DMADV, IoT can provide instant feedback on prototypes and product usage, ensuring customer needs are built into the design phase.

4. Automation and RPA (Robotic Process Automation)

Automation helps businesses execute DMAIC improvements at scale, ensuring consistency and cost savings. At the same time, DMADV projects can benefit from RPA by simulating workflows and testing new designs before they go live.

5. Cloud-Based Collaboration

Cloud technology makes DMADV and DMAIC projects more agile. Teams can share designs, data, and analytics seamlessly, whether they’re optimizing an existing process or building something entirely new. This reduces silos and accelerates decision-making.

Both DMAIC and DMADV are powerful Six Sigma tools, but their application depends on the project’s nature. DMAIC strengthens existing processes by eliminating inefficiencies, while DMADV fosters innovation by designing customer-focused solutions from scratch.

For businesses, the choice isn’t about which is better overall; it’s about which fits the project’s goals. By understanding the differences, leaders can save resources, improve efficiency, and drive innovation.

Looking to apply DMADV or DMAIC in your business projects? Connect with our Six Sigma experts at [email protected] and find the right fit today.