Why QA and QC Are Essential for Error Free Results

Learn why QA and QC are important, how they prevent errors, ensure product and service quality, and improve processes to deliver error-free results.

Have you ever wondered why some products or services consistently meet high standards, while others fall short? Even minor errors in manufacturing, software, or services can cost businesses millions and damage customer trust. This is where QA and QC practices play a critical role.

Quality Assurance (QA) and Quality Control (QC) are often mentioned together, but they serve distinct purposes. QA focuses on preventing errors before they occur, while QC identifies defects after the product or service is created. Together, they form a strong system that ensures error-free results.

Understanding QA and QC

Let’s understand what QA and QC actually mean:

-

Quality Assurance (QA): A proactive approach aimed at preventing defects. QA involves planning, designing, and implementing processes that ensure quality from the start. Think of it as setting the rules and standards that guide production.

-

Quality Control (QC): A reactive approach that identifies defects in products or services after they are created. Quality control involves testing, inspections, and measurements to detect errors before the product reaches the customer.

Together, these methods form a complete quality management system. While QA focuses on process improvement, QC ensures that outputs meet those standards.

Why QA and QC Practices Are Critical

1. Minimize Errors and Defects

Errors are costly. In software, a small bug can lead to system failures, in manufacturing, even minor defects can cause product recalls. By implementing QA and QC practices, businesses can significantly reduce errors and ensure products meet quality standards.

For example, automobile manufacturers use high standards of QA processes to design vehicles and QC tests to inspect every component before it leaves the factory. This combination minimizes the risk of accidents caused by defective parts.

2. Enhance Customer Satisfaction

Customers expect reliable, high-quality products and services. Any defect can lead to dissatisfaction, complaints, or loss of trust. Businesses that implement strong QA and QC practices consistently deliver error-free products, building credibility and long-term customer loyalty.

Consider a smartphone company that carefully tests every device before shipment. QA ensures the software is strong, while QC checks hardware for defects. As a result, customers receive reliable products, improving brand reputation.

3. Reduce Costs and Save Time

Many companies underestimate the cost of errors. Fixing defects after production is far more expensive than preventing them. QA processes help identify potential problems early, while QC ensures any remaining defects are caught before the product reaches the market.

For instance, in pharmaceutical manufacturing, QA and QC are critical. A single batch with errors can lead to massive financial loss, regulatory penalties, and health risks. Investing in quality systems prevents these issues and reduces waste.

4. Meet Regulatory Compliance

Various industries, from healthcare to construction, are regulated by strict quality standards. QA and QC practices help organizations comply with these standards, avoiding legal issues and penalties.

For example, medical device manufacturers must follow ISO 13485 guidelines. QA ensures design processes meet regulatory requirements, and QC verifies that the final product conforms to standards. Without proper QA and QC, compliance becomes impossible.

5. Improve Employee Productivity

QA and QC practices also streamline processes, clarify responsibilities, and reduce rework. Employees spend less time fixing errors and more time on productive tasks. This structured approach creates a more efficient work environment and boosts morale.

QA and QC in Action

Let’s look at a practical example. A leading electronics company, ElectroTech, was facing high return rates due to defective circuit boards.

-

QA measures: They revised their production processes, standardized procedures, and trained staff on error prevention.

-

QC measures: They implemented rigorous testing at multiple production stages, detecting faulty boards before shipment.

Within six months, product defects decreased by 70%, customer complaints dropped significantly, and overall production efficiency improved. This example shows that effective QA and QC practices are not just theoretical they deliver measurable results.

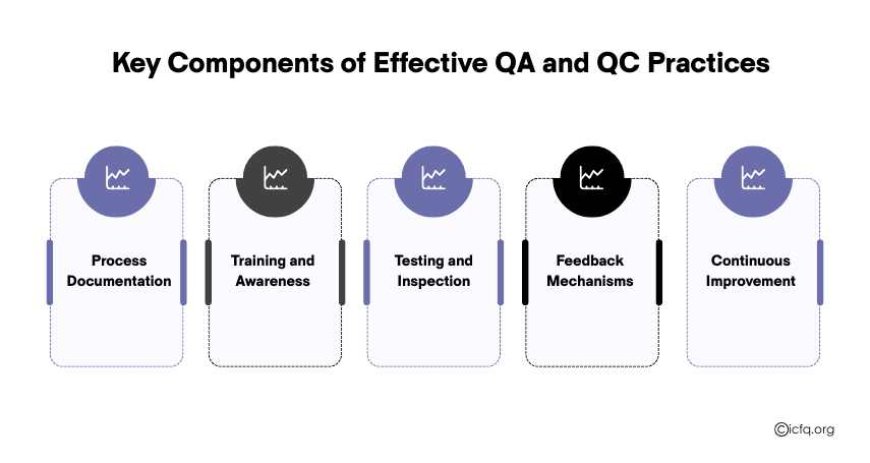

Key Components of Effective QA and QC Practices

Implementing QA and QC successfully requires a structured approach. Here are the main components:

-

Process Documentation: Clearly document processes, standards, and responsibilities to prevent errors.

-

Training and Awareness: Employees must understand quality standards and their role in maintaining them.

-

Testing and Inspection: Regular QC inspections ensure that products meet quality standards.

-

Feedback Mechanisms: Collect and analyze data from production and customer feedback to improve processes.

-

Continuous Improvement: Use insights from QA and QC to refine processes, reduce errors, and enhance efficiency.

Best Practices to Implement QA and QC

For businesses looking to improve quality and error-free results, here are practical steps to implement QA and QC practices:

-

Set Clear Standards: Define measurable quality standards for every stage of production or service delivery.

-

Use Automated Tools: Where possible, use software for testing, monitoring, and reporting defects. Automation reduces human errors.

-

Conduct Regular Audits: Periodic reviews of processes and outputs help identify gaps and opportunities for improvement.

-

Encourage a Quality Culture: Make quality everyone’s responsibility, from management to frontline staff.

-

Analyze and Act on Data: Use QC data to identify trends and implement proactive QA improvements.

Benefits of Consistent QA and QC Practices

-

Error-Free Products: Reduced defects lead to high-quality outputs.

-

Customer Loyalty: Satisfied customers are more likely to return and recommend your brand.

-

Cost Efficiency: Preventing errors is cheaper than fixing them after production.

-

Regulatory Compliance: Helps meet industry standards and avoid legal issues.

-

Employee Confidence: Staff work more efficiently when processes are clear and reliable.

The Role of Technology in QA and QC

Modern technology enhances QA and QC practices significantly:

-

Automated Testing: Software testing tools detect bugs faster and more accurately.

-

Data Analytics: Quality data helps predict defects and improve processes proactively.

-

IoT Sensors: In manufacturing, sensors monitor production in real time, reducing errors.

-

AI and Machine Learning: Predictive models can identify potential quality issues before they occur.

By using this technology, businesses can make QA and QC practices more efficient and precise.

Common Mistakes to Avoid

Even with QA and QC in place, mistakes happen. Common pitfalls include:

-

Ignoring Employee Training: Staff must understand quality processes to follow them effectively.

-

Overlooking Feedback: Customer complaints and QC data are valuable sources of improvement.

-

Inconsistent Processes: QA and QC only work when applied consistently across all operations.

-

Focusing Only on QC: Detecting defects is important, but preventing them through QA is more effective.

Avoiding these mistakes ensures that QA and QC practices deliver the best results.

Future of QA and QC

The future of QA and QC is moving toward smarter, faster, and more integrated systems:

-

AI-Driven Quality Systems: Automation and machine learning will detect issues in real-time.

-

Predictive Analytics: Anticipating defects before they occur will reduce errors further.

-

Integrated QA/QC Platforms: Combining QA and QC into a single platform for seamless management.

-

Global Quality Standards: Increasing international standards will require more structured QA and QC practices.

Businesses that adopt these trends early will achieve higher efficiency and fewer errors.

QA and QC are not just optional practices- they are essential for any organization that wants error-free results. From preventing costly mistakes to ensuring customer satisfaction, compliance, and efficiency, their impact cannot be overstated.

Start implementing QA and QC practices today to ensure every product, service, or process you deliver is reliable, accurate, and trusted by your customers. Your commitment to quality is your commitment to excellence.