Comprehensive Guide to Lean Six Sigma Course

Boost your career with our Lean Six Sigma Course. Learn key principles, methods, and certification details to enhance your skills.

Lean Six Sigma methodologies are now a global standard in many industries that aim to boost efficiency and enhance quality. This combination of strategies effectively streamlines production, reduces waste, and cuts down on defects. These improvements lead to better performance and higher customer satisfaction. Businesses around the world, including in sectors like manufacturing, healthcare, and finance, use Lean Six Sigma to improve their operations and encourage ongoing improvement. The success of this approach has made it a key part of the operational strategy for many leading companies, helping them stay competitive in their markets.

Combining Lean Efficiency with Six Sigma Quality

Lean Six Sigma merges two powerful operational improvement methods: Lean and Six Sigma. Lean focuses on eliminating non-value-added activities (waste), thereby speeding up processes and reducing costs. It targets inefficiencies such as excess inventory, unnecessary motion of people or equipment, and overproduction. On the other hand, Six Sigma is primarily concerned with reducing process variability and defects through a data-driven approach and rigorous process analysis. This method uses a set of quality management tools, including statistical analysis, along with a structured methodology based on the DMAIC (Define, Measure, Analyze, Improve, Control) phases.

By merging these approaches, Lean Six Sigma helps businesses operate more efficiently and produce higher-quality results. It does this by both speeding up processes and making them more consistent, which enhances overall effectiveness and reliability. This dual focus on efficiency and quality makes Lean Six Sigma a popular choice for organizations looking to achieve operational excellence.

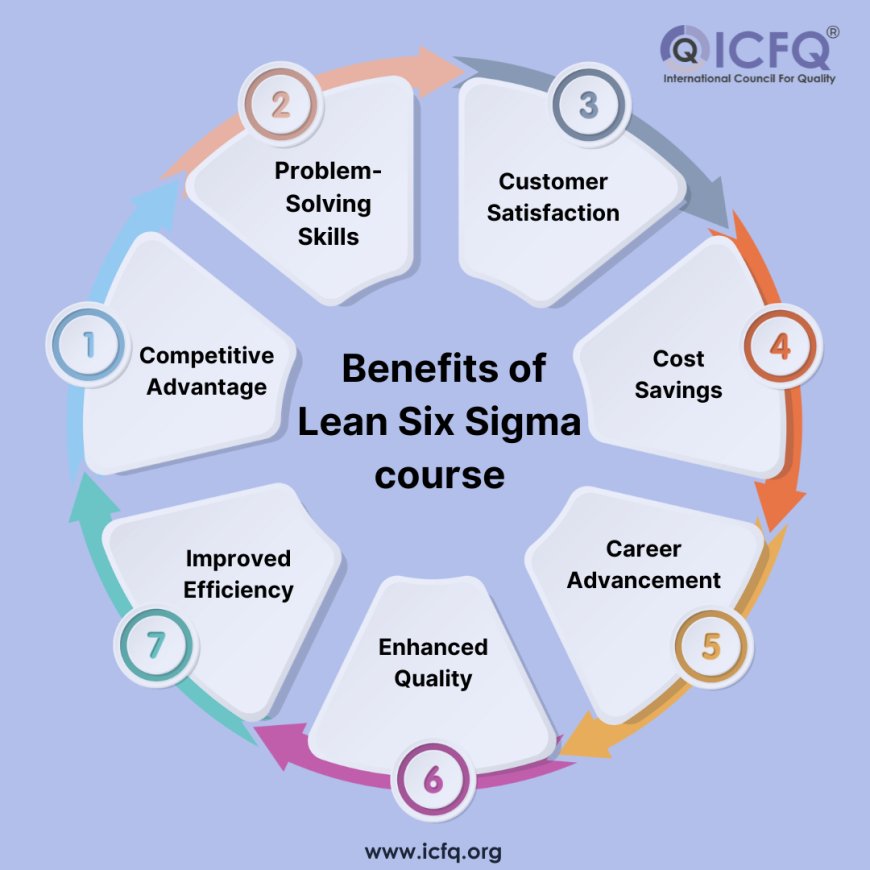

What are the benefits of taking a Lean Six Sigma course?

These benefits make Lean Six Sigma courses valuable for professionals looking to enhance their skills and contribute more effectively to their organizations. Taking a Lean Six Sigma course offers several benefits:

-

Improved Efficiency: Learn techniques to streamline processes, reduce waste, and increase productivity.

-

Enhanced Quality: Gain skills to reduce errors and defects, leading to better quality products or services.

-

Career Advancement: Certification can open up new job opportunities and potential for promotions.

-

Cost Savings: Apply methods to reduce operational costs by identifying and eliminating inefficiencies.

-

Customer Satisfaction: Improve processes to deliver better products or services, resulting in happier customers.

-

Problem-Solving Skills: Develop strong analytical and problem-solving abilities to address business challenges effectively.

-

Competitive Advantage: Help your organization stand out by implementing effective process improvements.

Guidelines on choosing the right course

When selecting the right course, especially for Lean Six Sigma or similar areas, it's crucial to make an informed decision based on several factors:

1. Factors to Consider

-

Accreditation: Ensure the course is accredited by a recognized body. Accreditation means the course meets high educational standards and is recognized in the industry.

-

Curriculum: Review the curriculum carefully to ensure it covers all necessary topics comprehensively. It should include both theoretical concepts and practical applications relevant to your career goals.

-

Instructor Qualifications: Check the qualifications and experience of the instructors. Instructors should have real-world experience and a solid teaching background in Lean Six Sigma.

-

Practical Application Opportunities: Look for courses that offer practical experiences such as live projects, case studies, and simulations. These help translate theory into practice and enhance learning.

2. Insights into Evaluating Course Effectiveness

-

Alumni Success: Research the success of past students. Alumni employment and advancement in their fields can indicate the effectiveness of the course.

-

Course Reviews: Read reviews from former students to gauge their experiences. Pay attention to comments on the quality of teaching, the applicability of the course content, and the support provided throughout the course.

By considering these guidelines, you can choose a course that not only fits your professional needs but also provides a robust learning experience that enhances your career prospects.

Who Should Enroll in Lean Six Sigma Courses?

Lean Six Sigma courses are designed to cater to a variety of professionals interested in improving business processes, reducing waste, and increasing efficiency. Here’s a breakdown of the target audience and prerequisites for each level:

Lean Six Sigma Course Requirements and Audience

-

Yellow Belt: Ideal for beginners with no required prerequisites. It suits team members who need a basic understanding of Lean Six Sigma for occasional project involvement.

-

Green Belt: For professionals who participate in or lead small projects. Some experience in project management or familiarity with Lean Six Sigma is beneficial, but not mandatory. This level is good for managers and leaders who apply these methods to improve their team's processes.

-

Black Belt: Designed for those who manage large projects and are involved in strategic decisions within their organizations. Black Belts also trains and mentors Green Belts, making this level suitable for senior managers and consultants.

-

Master Black Belt: For top-level professionals who oversee multiple projects and lead the strategic implementation of Lean Six Sigma across the organization. Extensive Lean Six Sigma experience and strong leadership skills are essential for this level.

Each level addresses different professional needs and prepares individuals for specific roles in improving business processes and efficiencies.

Key Components of Lean Six Sigma Training

A. Curriculum and Learning Outcomes

The curriculum of Lean Six Sigma training is designed to provide a comprehensive understanding of the methodologies used to reduce waste and improve quality in various business processes. Learning outcomes typically focus on:

-

Understanding the core principles of Lean and Six Sigma.

-

Learning to identify and eliminate non-value-adding activities.

-

Gaining proficiency in data analysis to make informed decisions.

-

Developing skills to lead and manage project teams effectively.

Each belt level has specific outcomes, with complexity increasing from Yellow to Master Black Belt.

B. Practical Applications and Case Studies

Lean Six Sigma training often includes numerous case studies and real-world examples to illustrate the practical application of the concepts taught. These include:

-

Industry-specific scenarios that demonstrate how Lean Six Sigma can be applied to solve real business problems.

-

Interactive simulations and role-playing exercises that allow participants to practice implementing Lean Six Sigma tools in a controlled environment.

-

Analysis of past projects with a focus on what worked, what didn’t, and how problems were resolved.

This component is crucial as it helps learners see the tangible impact of Lean Six Sigma techniques and prepares them for similar challenges in their workplaces.

C. Tools and Techniques Taught in the Course

The training provides detailed instruction on a variety of tools and techniques to the Lean Six Sigma approach, including:

-

DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify) methodologies for managing projects.

-

Statistical tools like control charts, regression analysis, and hypothesis testing to analyze data.

-

Process mapping and value stream mapping to visualize and streamline workflows.

-

5S, Kanban, and Poka-yoke (error-proofing) techniques to improve organization and reduce errors in the workplace.

These tools are the backbone of Lean Six Sigma initiatives, equipping professionals with the skills needed to drive significant improvements in their organizations.

Lean Six Sigma courses are essential for both professional and organizational development as they provide key skills in process improvement and quality management. These courses equip individuals with the tools to enhance efficiency and quality in their work, contributing significantly to their organization's performance. If you're looking to improve your skills and help your organization achieve better operational outcomes, enrolling in a Lean Six Sigma course can be a strategic move for your career growth and professional advancement.