What Is Quality Systems Certification & Why It Matters

Find out how quality systems certification helps businesses stay efficient, compliant, and trusted by their customers.

Have you ever wondered how some businesses consistently deliver high-quality products and services while others struggle with errors, delays, or customer complaints?

Do you know what gives industry leaders an edge, helping them build trust, stay compliant with regulations, and run operations efficiently?

The secret often lies in implementing strong quality systems and achieving formal QMS certification. Businesses that adopt certified quality systems and obtain a quality management system certificate often report higher operational efficiency, fewer defects, and stronger customer satisfaction, key factors that drive long-term growth and credibility.

Recent data shows that businesses with certified quality systems experience significant improvements in their operations. Companies report up to 25% higher operational efficiency with standardized processes and streamlined workflows that reduce waste and increase productivity.

What Is Quality Systems Certification and Why It Matters?

Quality systems certification is an official recognition awarded to organizations that comply with established quality management system certificate standards, such as ISO 9001, ISO 14001, or industry-specific standards. Certification demonstrates that a company has implemented processes and controls to deliver consistent quality, reduce risks, and enhance customer satisfaction.

Benefits of certification include:

-

Improved efficiency: Streamlined processes reduce waste and errors.

-

Regulatory compliance: Certifications help organizations meet legal and industry requirements.

-

Customer confidence: Verified standards build trust with clients and stakeholders.

-

Competitive advantage: Certification differentiates a company in the marketplace.

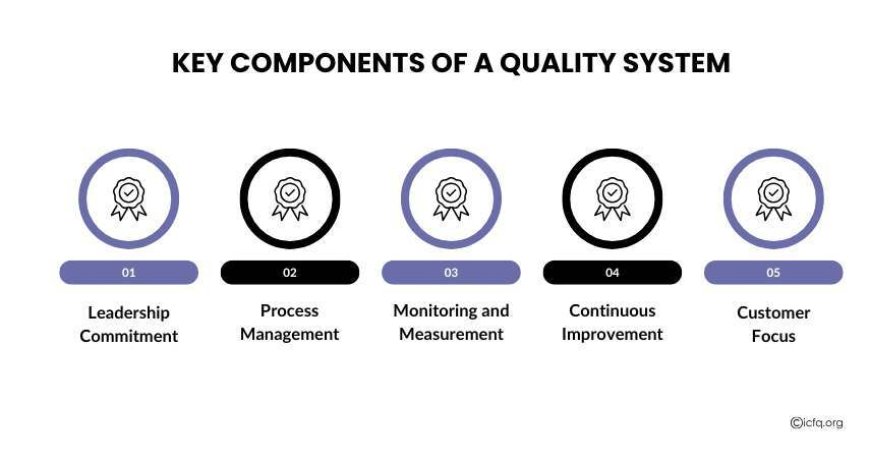

Key Components of a Quality System

Leadership Commitment

Strong quality systems require top management involvement to ensure that quality objectives align with business goals. Leadership sets the tone for a culture of quality throughout the organization.

Process Management

Clear documentation of processes, roles, and responsibilities ensures repeatable and predictable outcomes, minimizing errors and inefficiencies. This is critical for any Process Quality System department to function effectively.

Monitoring and Measurement

Regular audits, inspections, and performance reviews help identify deviations from quality standards and enable corrective actions.

Continuous Improvement

Quality systems emphasize Kaizen or continuous improvement, ensuring that processes evolve to meet changing customer needs and industry standards.

Customer Focus

A strong quality system always prioritizes customer satisfaction, incorporating feedback into process enhancements and product improvements.

Types of Quality Systems Certifications

ISO 9001: Quality Management System (QMS)

The most widely recognized certification, ISO 9001, focuses on process efficiency, continuous improvement, and customer satisfaction. Achieving qms certification under ISO 9001 ensures that a business has robust quality systems in place.

ISO 14001: Environmental Management System (EMS)

ISO 14001 ensures that companies manage environmental responsibilities systematically, often complementing ISO 9001.

Industry-Specific Certifications

Certain sectors, such as automotive, healthcare, and food, require specialized types of quality certifications to meet regulatory and industry standards. Examples include IATF 16949 for automotive and ISO 22000 for food safety.

Why Quality Systems Certification Matters

-

Enhances Customer Trust

Certification signals to customers that the organization adheres to recognized quality systems, ensuring reliable products and services.

-

Improves Operational Efficiency

Formalized quality systems help identify inefficiencies, reduce errors, and optimize resource utilization, leading to cost savings.

-

Ensures Regulatory Compliance

Many industries require documented quality systems to meet national or international regulations. Certification demonstrates compliance and reduces the risk of legal penalties.

-

Provides a Competitive Advantage

Certified organizations often stand out in competitive markets, attracting more clients, improving credibility, and supporting business growth.

-

Drives Continuous Improvement

Quality systems foster a culture of ongoing improvement, enabling organizations to adapt processes, reduce risks, and enhance performance over time.

Steps to Achieve Quality Systems Certification

Assess Current Processes

Evaluate existing procedures and identify gaps compared to standard quality systems requirements.

Develop a Quality Management Plan

Document processes, roles, responsibilities, and monitoring methods to meet certification standards.

Train Employees

Ensure all staff understand their roles in maintaining quality and adhering to documented procedures.

Implement and Monitor Systems

Put processes into action and regularly monitor performance through audits and inspections.

Conduct Internal Audits

Review systems internally to identify non-conformities and areas for improvement before the official audit.

Certification Audit

Engage an accredited certification body to verify compliance with quality management system certificate standards and issue certification.

Continuous Improvement

After certification, continue monitoring, reviewing, and refining processes to maintain standards and improve efficiency.

The Business Impact of Certified Quality Systems

Implementing certified quality systems goes beyond compliance, it delivers tangible benefits that impact nearly every aspect of a business. Organizations that invest in quality systems often experience improved efficiency, stronger customer trust, and a healthier bottom line.

Enhanced Operational Efficiency

Certified quality systems standardize processes, reduce errors, and streamline workflows. This leads to faster production cycles, lower costs, and more predictable outcomes. Businesses can allocate resources more effectively, improving overall productivity and profitability.

Increased Customer Confidence

Certification demonstrates a company’s commitment to delivering consistent quality. Customers and clients are more likely to trust and engage with businesses that maintain recognized quality systems, leading to higher customer satisfaction, loyalty, and repeat business.

Risk Mitigation and Compliance

Quality systems help organizations identify potential risks and implement preventive measures. They also ensure adherence to regulatory and industry standards, reducing the likelihood of legal penalties, product recalls, or reputational damage.

Competitive Advantage

Businesses with certified quality systems often stand out in the market, as certification signals reliability and professionalism. This can lead to new business opportunities, partnerships, and access to global markets, giving companies an edge over competitors without certification.

Continuous Improvement Culture

Certified quality systems encourage a culture of ongoing evaluation and improvement, enabling businesses to refine processes, adapt to market changes, and sustain long-term growth.

Quality systems certification is more than a badge, it is a strategic investment in consistency, compliance, and customer trust. By implementing robust quality systems, organizations can reduce errors, streamline operations, and differentiate themselves in competitive markets.

Businesses looking to strengthen their quality department and achieve measurable growth can start by assessing current processes, training staff, and seeking the right certification to meet industry standards.

Ready to take your business to the next level with certified quality systems?

Reach out to us at [email protected] for personalized guidance and expert support!