What is the Six Sigma concept

Learn about the Six Sigma concept and how it drives process improvement. Find out how this powerful methodology helps businesses reduce defects and increase efficiency

The Six Sigma concept is used to improve processes by reducing defects and minimizing variability. It focuses on using data and statistical tools to enhance efficiency and ensure consistent quality in products and services. This approach helps organizations achieve better performance and continuous improvement in their operations.

The Fundamentals of Six Sigma Concepts

Six Sigma is a set of concepts aimed at improving process quality by identifying and eliminating the causes of defects. Motorola originally developed it in the 1980s and has since become a widely recognized methodology in many industries, from manufacturing to healthcare to software development.

The term "Six Sigma" refers to a statistical measure that indicates the quality of a process. In a Six Sigma process, the goal is to have fewer than 3.4 defects per million opportunities (DPMO). In simple terms, Six Sigma seeks to reduce process variation to the point where the likelihood of defects is almost negligible.

A key element of Six Sigma is its focus on using data to drive decisions. By analyzing data and applying statistical methods, organizations can identify the root causes of problems and implement changes to improve efficiency and reduce variability in their processes.

The DMAIC Framework: The Heart of Six Sigma

One of the key concepts in Six Sigma is the DMAIC framework, which stands for Define, Measure, Analyze, Improve, and Control. This systematic, step-by-step approach helps organizations implement process improvements and measure their success.

-

Define: The first step is to define the problem or project. This involves identifying the key issues and setting clear goals for process improvement.

-

Measure: Once the problem is defined, the next step is to measure the current performance of the process. This involves collecting data to understand how well the process is functioning and where improvements can be made.

-

Analyze: In this phase, the collected data is analyzed to identify the root causes of the defects or inefficiencies in the process. By understanding the underlying issues, teams can determine the best course of action.

-

Improve: Based on the analysis, the next step is to implement changes to improve the process. These changes are designed to eliminate defects and increase process efficiency.

-

Control: Finally, the control phase ensures that the improvements are sustained over time. This involves monitoring the process to ensure that the changes remain effective and that any future issues are addressed quickly.

The DMAIC framework is central to Six Sigma concepts because it provides a structured methodology for tackling complex problems and improving processes.

Six Sigma Roles and Certifications

Six Sigma is not a one-size-fits-all methodology. It offers different levels of certification to cater to individuals at various stages of their careers and expertise in quality management. The Six Sigma concepts are categorized into belts, which represent different levels of knowledge and responsibility within a Six Sigma project.

-

Six Sigma Yellow Belt: This is the entry-level certification, which introduces individuals to the basics of Six Sigma and how it contributes to process improvement. Yellow Belts typically assist with data collection and support improvement projects.

-

Six Sigma Green Belt: This intermediate certification is for those who actively manage or work on improvement projects using Six Sigma methods. Green Belts are often part of teams working to solve specific process issues.

-

Six Sigma Black Belt: The Black Belt certification is for individuals who have advanced expertise in Six Sigma and lead large-scale projects. Black Belts are responsible for managing teams, guiding improvement initiatives, and ensuring that Six Sigma concepts are applied effectively.

-

Six Sigma Master Black Belt: The highest level of Six Sigma certification, Master Black Belts are experienced leaders who mentor other belts and oversee complex initiatives. They play a strategic role in implementing Six Sigma across an organization.

These certifications ensure that individuals have the necessary skills and knowledge to apply Six Sigma concepts effectively, driving long-term improvements in their organizations.

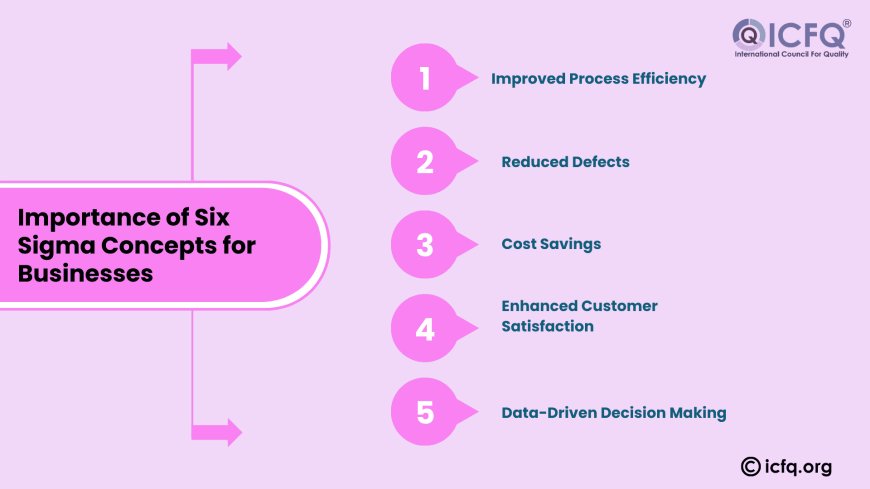

Why Six Sigma Concepts Are Important for Businesses

The importance of Six Sigma concepts cannot be overstated. Organizations that embrace Six Sigma benefit from numerous advantages, including:

-

Improved Process Efficiency: Six Sigma focuses on eliminating inefficiencies and reducing waste, which leads to better use of resources and faster processes.

-

Reduced Defects: By reducing variation in processes, Six Sigma helps organizations reduce defects and errors, which ultimately leads to higher-quality products and services.

-

Cost Savings: As processes become more efficient and defects decrease, businesses can save money by reducing rework, scrap, and waste.

-

Enhanced Customer Satisfaction: Six Sigma helps organizations deliver high-quality products and services consistently, which leads to improved customer satisfaction and loyalty.

-

Data-Driven Decision Making: The use of data and statistical analysis in Six Sigma ensures that decisions are based on facts rather than assumptions, leading to more accurate and effective improvements.

How Six Sigma Drives Continuous Improvement in Organizations

Six Sigma helps businesses by providing a framework for continuous improvement. By reducing variation in processes, it ensures that organizations are constantly improving their operations and achieving greater efficiency and consistency. Some key aspects of continuous improvement through Six Sigma include:

-

Identifying root causes of inefficiencies that can be improved over time.

-

Fostering a culture of ongoing learning and development within the organization.

-

Enabling regular performance reviews to make sure improvements are sustained.

-

Tracking progress with data to ensure continuous operational enhancements.

Why Data-Driven Decision Making is Central to Six Sigma Concepts

Six Sigma focuses on using data and analysis to guide decision-making. This approach ensures that changes to processes are based on solid information rather than guesses, helping organizations achieve lasting improvements. Key points about data-driven decision-making include:

-

Using data to identify trends and patterns that influence process outcomes.

-

Analyzing root causes of problems and inefficiencies through statistical methods.

-

Measuring improvements quantitatively to verify success and guide further actions.

-

Making informed decisions based on empirical evidence rather than intuition ensures more reliable results.

The Future of Six Sigma Concepts

As industries continue to evolve, Six Sigma will remain a critical tool for organizations striving for operational excellence. While the methodology has been around for decades, its principles are still highly relevant today. Six Sigma has evolved to incorporate modern technologies, such as data analytics and machine learning, making it even more powerful in driving improvements.

Adopting Six Sigma concepts helps organizations improve their processes and tackle business challenges more effectively. By focusing on continuous improvement and reducing inefficiencies, businesses can achieve growth, enhance profitability, and stay competitive.